EVOP Simplex: A Comprehensive Guide to Process Optimization in Pharmaceutical Development and Manufacturing

This article provides a detailed exploration of the Evolutionary Operation (EVOP) Simplex methodology for process improvement, specifically tailored for researchers, scientists, and drug development professionals.

EVOP Simplex: A Comprehensive Guide to Process Optimization in Pharmaceutical Development and Manufacturing

Abstract

This article provides a detailed exploration of the Evolutionary Operation (EVOP) Simplex methodology for process improvement, specifically tailored for researchers, scientists, and drug development professionals. It begins by establishing the foundational principles of EVOP and the Simplex algorithm, explaining their synergy in navigating complex experimental landscapes. The core section delivers a rigorous methodological framework for application in real-world pharmaceutical scenarios, including formulation development and bioprocess optimization. The guide then addresses critical troubleshooting techniques and optimization strategies to overcome common experimental pitfalls. Finally, it examines validation protocols and comparative analyses with other Design of Experiments (DoE) approaches, such as Response Surface Methodology (RSM). The conclusion synthesizes key learnings and discusses future implications for enhancing efficiency, quality, and regulatory compliance in biomedical research and clinical manufacturing.

What is EVOP Simplex? Understanding the Core Principles for Process Scientists

Evolutionary Operation (EVOP) is a sequential process optimization methodology developed for continuous improvement of industrial processes with minimal disruption. This whitepaper details its historical development, core principles, and modern applications, with a specific focus on its contextualization within a broader research thesis on the EVOP simplex algorithm for process improvement in scientific and pharmaceutical development.

Historical Development and Theoretical Foundation

Evolutionary Operation was formally introduced by George E. P. Box in 1957. The central thesis was that a production process could be run in a slightly altered manner to generate experimental data, which, when analyzed systematically, would lead to incremental improvements in yield, quality, or efficiency—all while maintaining routine output. This contrasted with traditional factorial experiments that required dedicated, disruptive runs.

The methodology evolved through key phases:

- 1950s-1960s (Classical EVOP): Focused on 2^k factorial designs run in cycles at the plant floor level. Results were presented on simple information boards for operators.

- 1970s-1980s (Simplex EVOP): Introduction of the sequential simplex algorithm by Spendley, Hext, and Himsworth (1962), later refined by Nelder and Mead (1965). This provided a more efficient path of experimentation towards an optimum by using geometric movements (reflection, expansion, contraction).

- 1990s-Present (Integration with QbD & PAT): EVOP principles have been integrated into modern pharmaceutical frameworks like Quality by Design (QbD) and Process Analytical Technology (PAT), enabling real-time process optimization and validation.

Core Algorithm: The EVOP Simplex

The simplex is a geometric figure with one more vertex than the number of factors. For two factors, it is a triangle. The algorithm proceeds iteratively by moving away from the vertex with the worst response.

Algorithm Protocol

- Initialization: Select

k+1initial vertices (a simplex) forkfactors. Measure the response (e.g., yield, purity) at each vertex. - Ranking: Rank vertices from best (B) to worst (W) response.

- Calculate Centroid (P): Compute the centroid of all vertices excluding the worst (W).

- Reflection: Generate a new point

R = P + α(P - W), where α (reflection coefficient) is typically 1. Evaluate response at R. - Decision & Iteration:

- If R is better than B, try Expansion:

E = P + γ(P - W), where γ (expansion coefficient) >1 (typically 2). Evaluate E. Use the better of E and R to replace W. - If R is worse than W, perform Contraction:

C = P + β(P - W), where β (contraction coefficient) is between 0 and 1 (typically 0.5). Evaluate C. If C is better than W, replace W with C. - If R is between other points, replace W with R.

- If R is better than B, try Expansion:

- Termination: The algorithm terminates when the simplex vertices converge or a predetermined number of cycles is reached.

Quantitative Comparison of Simplex Coefficients

Table 1: Standard Coefficients for Nelder-Mead (Simplex) EVOP

| Coefficient | Symbol | Standard Value | Function in Algorithm |

|---|---|---|---|

| Reflection | α | 1.0 | Generates a new point opposite the worst. |

| Expansion | γ | 2.0 | Explores further in a promising direction. |

| Contraction | β | 0.5 | Shrinks the simplex in a non-optimal region. |

| Shrinkage | δ | 0.5 | Rarely used; contracts all points toward the best. |

Modern Application Protocol in Drug Development

The following protocol outlines a typical EVOP simplex study for optimizing a Critical Process Parameter (CPP) in bioreactor conditions.

Experimental Protocol: Optimization of Bioreactor Yield

Objective: Maximize protein titer (mg/L) by adjusting two CPPs: Temperature (T) and Dissolved Oxygen (DO).

Pre-Experimental Setup:

- Define Operating Ranges: Based on prior knowledge, set feasible ranges: T: 34-38°C, DO: 20-60%.

- Select Initial Simplex: Choose three operating conditions (vertices) spanning the design space.

- Define Response: Primary: Final Titer (mg/L). Secondary: Viability (%).

- Establish Controls: Include a center point run to check for curvature or drift.

Cyclic Procedure (Per EVOP Cycle):

- Run Experiments: Conduct small-scale bioreactor runs (n=3 per vertex) in a randomized order to minimize batch effects.

- Measure & Analyze: Harvest, quantify titer via HPLC, and assess viability. Calculate average response per vertex.

- Apply Simplex Algorithm: Using the logic in Section 2.1, generate the new vertex condition for the next cycle.

- Safety & Quality Check: Ensure the new operating condition is within validated safe ranges and meets pre-defined quality thresholds (e.g., product aggregation <5%).

- Iterate: Continue until improvement between cycles is less than a pre-specified threshold (e.g., <2% titer increase) for three consecutive cycles.

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for a Bioreactor EVOP Study

| Item | Function in EVOP Experiment |

|---|---|

| Designated Small-Scale Bioreactors | Enable parallel, statistically relevant runs with controlled parameters (pH, DO, temp). |

| Chemically Defined Cell Culture Media | Provides consistent, reproducible nutrient base to isolate CPP effects. |

| Producer Cell Line (e.g., CHO-K1) | Standardized biological system expressing the target protein. |

| Analytical HPLC System with SEC | Quantifies target protein titer and critical quality attributes (e.g., aggregation). |

| Automated Cell Counter & Viability Analyzer | Provides rapid, precise measurements of cell growth and health (secondary response). |

| Statistical Process Control (SPC) Software | For real-time data analysis, visualization, and algorithm calculation of next simplex vertex. |

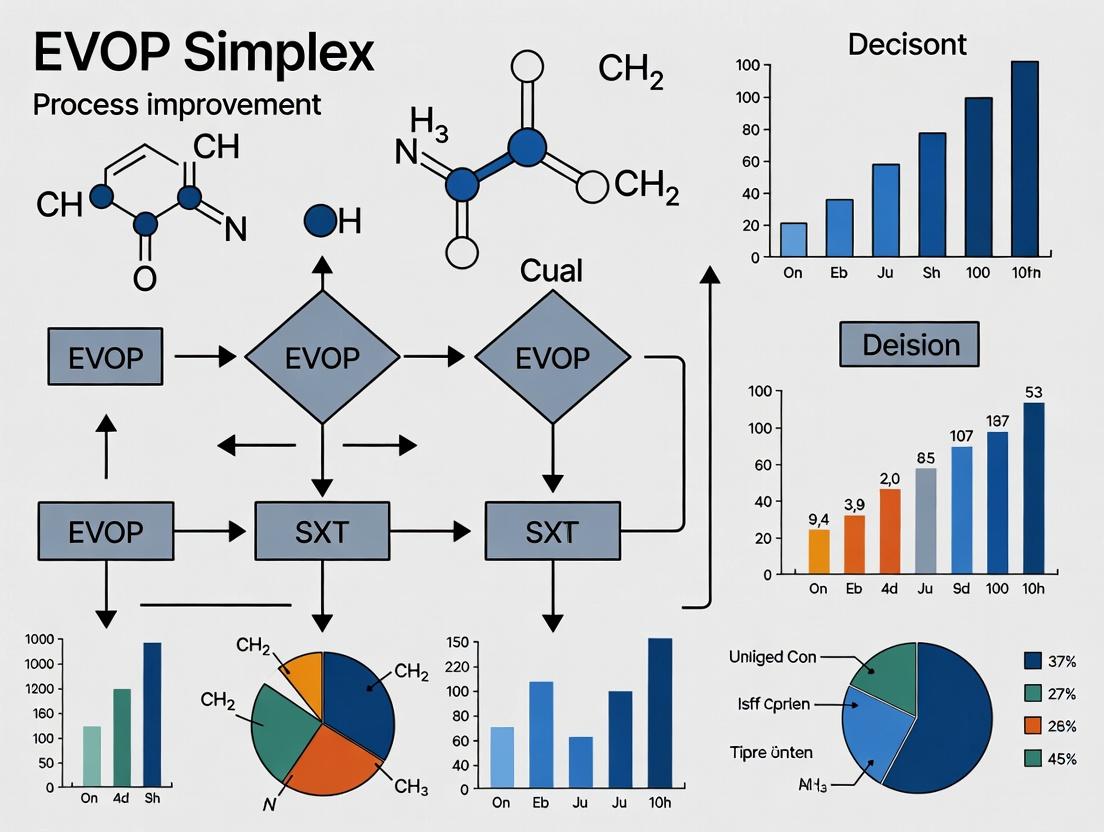

Visualizing the EVOP Simplex Workflow and Logic

Diagram 1: EVOP Simplex Algorithm Decision Logic Flow (84 chars)

Diagram 2: Simplex Geometric Operations (Factor Space) (49 chars)

Within the thesis context of EVOP simplex for process improvement research, this methodology is not a historical artifact but a living framework. Its sequential, frugal nature aligns with the principles of lean development and QbD. Modern research focuses on hybridizing the simplex with model-based approaches (e.g., Bayesian optimization), integrating real-time PAT data for adaptive simplex movements, and extending its application to complex biological systems with multiple, often conflicting, quality responses. EVOP remains a foundational tool for the systematic, empirical pursuit of process optimality.

This whitepaper elucidates the geometric principles of the Simplex Algorithm, contextualized within Evolutionary Operation (EVOP) simplex methodologies for process optimization in pharmaceutical development. We provide a rigorous technical exposition suitable for researchers and scientists engaged in drug process improvement, integrating current experimental protocols and reagent toolkits.

The Simplex algorithm, a cornerstone of linear programming (LP), provides a systematic geometric method for traversing the vertices of a feasible region—a convex polytope—to find an optimal solution. In pharmaceutical research, particularly in drug development, the EVOP simplex method is a cornerstone for continuous process improvement. It enables the efficient optimization of critical process parameters (CPPs)—such as temperature, pH, reaction time, and catalyst concentration—to maximize yield, purity, or efficiency while minimizing cost and impurities, all with minimal experimental disruption to ongoing production.

Geometric Foundations of the Simplex Algorithm

The algorithm operates on a feasible region defined by linear constraints. Geometrically, it moves from one vertex (a basic feasible solution) to an adjacent vertex along an edge, always improving the objective function value until an optimum is reached.

Core Quantitative Data

Table 1: Key Computational Complexities of Simplex Variants

| Simplex Variant | Average Case Complexity | Worst-Case Complexity | Primary Use Case in EVOP |

|---|---|---|---|

| Revised Simplex | O(m² + mn) | Exponential | Standard full-scale optimization |

| EVOP Sequential Simplex | O(n²) per iteration | Polynomial | Continuous on-line process adjustment |

| Two-Phase Simplex | O(m²n) | Exponential | Handling problems with ≥ constraints |

Table 2: Typical EVOP Simplex Parameters in Pharmaceutical Process Optimization

| Parameter | Typical Range | Impact on Response (Yield/Purity) | Optimization Goal |

|---|---|---|---|

| Temperature (°C) | 20 - 80 | High (Non-linear) | Maximize |

| pH | 6.0 - 8.5 | Critical (Quadratic) | Target 7.2 ± 0.2 |

| Reaction Time (hr) | 1 - 24 | Moderate | Minimize (to reduce cost) |

| Catalyst Conc. (%) | 0.1 - 2.0 | High (Linear near optimum) | Optimize for cost vs. yield |

Experimental Protocol: Implementing EVOP Simplex for Reaction Optimization

The following detailed methodology is adapted from recent publications on drug synthesis optimization.

Protocol: Sequential Simplex Optimization of an API Synthesis Step

Objective: Maximize the yield of Active Pharmaceutical Ingredient (API) Intermediate B.

- Initial Simplex Formation: Select (n+1) initial vertices. For n=3 factors (Temperature-T, pH, Time-t), 4 experiments are designed.

- Vertex 1 (Baseline): T=50°C, pH=7.0, t=12h.

- Vertex 2: T=60°C, pH=7.0, t=12h.

- Vertex 3: T=50°C, pH=7.5, t=12h.

- Vertex 4: T=50°C, pH=7.0, t=16h.

- Experimentation & Response Evaluation: Conduct reactions at each vertex condition in a controlled reactor. Measure yield (%) of Intermediate B. Replicate center point for error estimation.

- Simplex Progression:

- Reflection: Identify the worst-performing vertex (lowest yield). Calculate its reflection through the centroid of the remaining vertices.

- New Experiment: Execute the reaction at the reflected point's coordinates.

- Decision Rule:

- If the reflected point yields better than the second-worst but not the best, accept it, forming a new simplex.

- If it yields the best result so far, try expansion.

- If it yields worse than the second-worst, try contraction.

- If it yields worse than the worst, try shrinkage towards the best vertex.

- Termination: The optimization is terminated when the simplex volume shrinks below a predefined threshold (e.g., <5% of initial volume) or the improvement in response between cycles is statistically insignificant (p>0.05 via ANOVA).

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for EVOP Simplex Experiments in API Development

| Item / Reagent Solution | Function in Optimization | Example Specification |

|---|---|---|

| Controlled Reactor System | Provides precise, adjustable environment for CPP variation (T, stirring). | Jacketed glass reactor with PID temperature control (±0.1°C). |

| pH Buffer Solutions | Enable accurate and stable adjustment of reaction pH, a critical CPP. | Certified aqueous buffers, pH 4.01, 7.00, 10.01 ±0.02. |

| HPLC-UV/MS System | Quantifies yield and purity of API/intermediates for objective function calculation. | C18 column, gradient elution, PDA & MS detection. |

| Design of Experiment (DoE) Software | Facilitates initial simplex design, data analysis, and progression calculation. | JMP, Modde, or custom Python/R scripts. |

| Process Analytical Technology (PAT) | Enables real-time monitoring of reactions (in-situ FTIR, FBRM). | ReactIR probe for concentration profiling. |

Visualizing the Algorithm and Workflow

Advanced Considerations & Current Research Trends

Modern implementations integrate the Simplex with machine learning for surrogate modeling, reducing physical experiments. Hybrid approaches using the Simplex to navigate a Design Space defined by Quality by Design (QbD) principles are pivotal in modern Pharmaceutical Quality Systems. Furthermore, the geometric intuition of Simplex is foundational for understanding more complex algorithms used in high-dimensional process spaces, such as in the optimization of biologics manufacturing.

1. Introduction

Within the framework of process improvement research, the optimization of complex systems—particularly in pharmaceutical development—demands methodologies that are both robust and resource-efficient. This whitepaper examines the synergistic integration of Evolutionary Operation (EVOP) and the Simplex optimization method. EVOP, a philosophy of continuous, on-line process adjustment using factorial designs, is inherently cautious and designed for full-scale production. The Simplex method, a sequential simplex algorithm, is a more aggressive, off-line optimization technique. Their synergy lies in applying Simplex's efficient directional search to achieve rapid improvement, followed by EVOP's statistical rigor to meticulously refine and validate the optimum within a noisy production environment. This combination forms a powerful thesis for a complete optimization lifecycle: rapid ascent via Simplex and robust exploitation via EVOP.

2. Foundational Methodologies

2.1 Evolutionary Operation (EVOP) EVOP involves the systematic introduction of small, planned variations in process factors during normal production. Its core is a repeated factorial design (typically 2^2 or 2^3) where results are accumulated over cycles until statistically significant effects are detected.

Experimental Protocol (Classical 2-Factor EVOP Cycle):

- Define two critical process variables (e.g., Reaction Temperature (T), Catalyst Concentration (C)).

- Set a base operating condition (nominal set point).

- For each production batch, apply one of five conditions in a cyclic order: (1) Base (T, C), (2) T+ΔT, C, (3) T-ΔT, C, (4) T, C+ΔC, (5) T, C-ΔC.

- Measure the critical quality attribute (e.g., yield, purity) for each batch.

- After one complete cycle (5 batches), calculate main effects and interaction effects.

- Accumulate data over multiple cycles. Once the standard error of the effect is small enough, determine if an effect is statistically significant (e.g., using a confidence interval).

- Permanently shift the base operating conditions in the direction of improvement indicated by significant effects.

- Repeat the cycle around the new base condition.

2.2 Modified Simplex Method (Nelder-Mead) The sequential simplex is a geometric figure in n-dimensional space with n+1 vertices. For two factors, it is a triangle. The algorithm iteratively reflects, expands, or contracts the simplex away from the worst-performing vertex.

Experimental Protocol (Modified Simplex for 2 Factors):

- Select n+1=3 initial experimental points that form a simplex in the factor space.

- Run experiments at each vertex and rank results: Best (B), Next-worst (N), Worst (W).

- Calculate the centroid (P) of all vertices except W.

- Reflect: Generate Reflection point R = P + (P - W). Run experiment at R.

- If R is better than B, try Expansion: E = P + γ(P - W), γ>1. Run experiment at E. Accept best of E and R.

- If R is between B and N, replace W with R to form a new simplex.

- If R is worse than N, try Contraction:

- If R is worse than W, try Contraction Inside: C = P - β(P - W), 0<β<1.

- If R is better than W, try Contraction Outside: C = P + β(P - W).

- Run experiment at C. If C is better than W, replace W with C. Otherwise, proceed to step 8.

- Reduction: If contraction fails, shrink the entire simplex toward B by reducing the distance of all vertices from B.

3. Synergistic Integration: A Phased Approach

The combined protocol leverages the strengths of both methods sequentially.

Phase 1: Simplex-Based Exploratory Ascent

- Objective: Rapidly move from the current operating region to the vicinity of the optimum.

- Protocol: Implement the Modified Simplex method (Section 2.2) as an off-line study using small-scale or pilot experiments. Continue until the simplex collapses or direction changes become minimal, indicating proximity to an optimum.

Phase 2: EVOP-Based Refinement and Validation

- Objective: Precisely locate the optimum and establish robust operating conditions with statistical confidence under full-scale production noise.

- Protocol: Use the best point from Phase 1 as the new center point for a classical EVOP program (Section 2.1). Implement the factorial design on the full-scale production line. The small variations of EVOP will finely map the response surface near the optimum and confirm its location with statistical rigor, ensuring the process is robust to normal variability.

4. Quantitative Data Comparison

Table 1: Comparative Analysis of EVOP and Simplex Methods

| Feature | Evolutionary Operation (EVOP) | Simplex Optimization |

|---|---|---|

| Primary Goal | Continuous, on-line process improvement & robustness | Rapid, off-line optimization to find an optimum |

| Experimental Scale | Full-scale production | Bench/Pilot scale |

| Step Size | Small, fixed increments (Δ) | Variable, adaptive steps |

| Underlying Design | Factorial (2^k) | Sequential simplex geometry |

| Statistical Foundation | Strong (uses ANOVA, confidence intervals) | Weak (heuristic, rule-based) |

| Risk to Production | Very Low | High (if applied directly to production) |

| Speed of Convergence | Slow, deliberate | Fast, efficient |

| Best Application Phase | Refinement & Validation | Exploratory Ascent |

Table 2: Hypothetical Yield Optimization Data in Drug Synthesis

| Experiment Phase | Factor 1: Temp (°C) | Factor 2: pH | Yield (%) | Purity (%) | Notes |

|---|---|---|---|---|---|

| Initial Production | 70 | 7.0 | 82.3 ± 1.5 | 98.1 ± 0.3 | Baseline (high variability) |

| Simplex Vertex 1 | 70 | 7.0 | 82.5 | 98.2 | Initial Worst (W) |

| Simplex Vertex 2 | 75 | 7.5 | 87.1 | 98.0 | Initial Next-worst (N) |

| Simplex Vertex 3 | 73 | 6.8 | 85.9 | 98.5 | Initial Best (B) |

| Simplex Reflection (R) | 78 | 7.3 | 89.4 | 98.7 | New Best Point |

| EVOP Cycle (at new center) | 78 ± 1 | 7.3 ± 0.2 | 89.6 ± 0.4 | 98.8 ± 0.1 | After 8 cycles, effect of Temp found significant (p<0.05) |

| Final Optimized Process | 79.2 | 7.3 | 90.1 ± 0.5 | 98.9 ± 0.1 | EVOP-directed shift, validated |

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for EVOP-Simplex Studies in Drug Development

| Item | Function in Experimentation |

|---|---|

| High-Throughput Screening (HTS) Assay Kits | Enables rapid, parallel analysis of yield/purity for multiple Simplex vertices or EVOP conditions. |

| Process Analytical Technology (PAT) Probes (e.g., inline pH, FTIR, FBRM) | Provides real-time, continuous data on critical quality attributes essential for both Simplex decision-making and EVOP cycle analysis. |

| Designated EVOP/DOE Software (e.g., JMP, Design-Expert, MODDE) | Used to design simplex sequences, randomize EVOP cycles, and perform statistical analysis of effects. |

| Stable Isotope-Labeled Reagents | Act as internal standards in analytical methods to improve measurement precision, crucial for detecting small EVOP effects. |

| Calibrated Chemical Feeding Pumps | Allows precise, automated adjustment of factor levels (e.g., catalyst feed rate) as dictated by Simplex or EVOP protocols. |

6. Visualized Workflows and Relationships

Title: Synergistic EVOP-Simplex Optimization Workflow

Title: Simplex Reflection Operation

Title: EVOP Two-Factor Design Layout

This technical guide, framed within the broader research thesis on Evolutionary Operation (EVOP) using simplex designs for continuous process improvement, details methodologies for de-risking pharmaceutical development. It outlines how systematic, iterative experimentation—inspired by EVOP principles—enables more efficient identification of optimal process parameters, directly translating to reduced attrition, accelerated timelines, and significant cost savings.

Evolutionary Operation (EVOP) is a strategy for process optimization that employs simple, iterative experimental designs to make continuous improvements with minimal disruption. The simplex method, a specific geometric EVOP design, facilitates navigation through a multi-factor experimental space to rapidly locate optimum conditions (e.g., yield, purity, bioavailability). In drug development, this philosophy is applied beyond manufacturing to critical stages like lead optimization, formulation, and process chemistry, systematically minimizing risk and cost.

Quantitative Impact: The Cost of Failure and Savings from Optimization

The financial imperative for risk mitigation is stark, as illustrated by recent industry data.

Table 1: The Cost of Pharmaceutical Development and Attrition (2022-2024 Data)

| Metric | Traditional Approach (Benchmark) | With Systematic QbD/EVOP-like Optimization | Data Source |

|---|---|---|---|

| Average Cost to Develop a New Drug | ~$2.3 Billion | Estimated 15-30% reduction in late-stage failures | Analysis of Tufts CSDD, IQVIA reports |

| Clinical Phase Transition Success Rates | Phase I to II: ~52%Phase II to III: ~28.9%Phase III to Submission: ~57.8% | Improvements driven by better candidate selection & formulation | BIO, Informa Pharma Intelligence (2023) |

| Preclinical Attrition Rate | ~45% (Safety/Efficacy) | Can be reduced via predictive ADMET & robust preclinical models | NCBI/Industry Reviews |

| Major Cost Driver | Late-stage clinical failure (~58% of total cost) | Risk shifted "left" through earlier, iterative experimentation | McKinsey & Company Analysis |

Table 2: Estimated Time and Resource Savings from Iterative DoE (Including Simplex)

| Development Stage | Traditional Trial-and-Error | Structured DoE/EVOP Approach | Key Benefit |

|---|---|---|---|

| Formulation Development | 12-18 months | 6-9 months | Faster identification of stable, bioavailable formulations. |

| Chemical Process R&D | 24+ months to final process | 15-18 months | Optimized yield, purity, and EHS profile earlier. |

| Analytical Method Dev. | 4-6 months per method | 2-3 months | Robust, validated methods with known design space. |

Core Methodologies: Implementing EVOP-Inspired Protocols

Protocol: Simplex Optimization for API Synthesis

Objective: Maximize yield and purity of a critical synthetic step.

- Define Variables: Select (n) critical process parameters (CPP), e.g., temperature, reactant stoichiometry, catalyst loading (n=3).

- Initial Simplex: Create an (n+1) initial experimental matrix (4 experiments for 3 factors) representing vertices of a simplex in factor space.

- Run & Rank: Execute experiments, measure responses (Yield, %Purity). Rank vertices from worst (W) to best (B).

- Generate New Point: Calculate the centroid of all points except W. Apply the reflection rule: New = Centroid + (Centroid – W).

- Iterate: Replace W with the new point if results improve. If not, use contraction or expansion steps per Nelder-Mead algorithm.

- Terminate: Stop when the simplex converges or response meets target.

Protocol: High-Throughput Formulation Screening (a Fed-Batch EVOP Analog)

Objective: Identify a formulation design space ensuring stability and dissolution.

- Define Design Space: Excipient types, ratios, and process variables (blending time, compression force).

- Micro-Experiment Design: Use a fractional factorial or Plackett-Burman design to screen a wide space with minimal runs (e.g., 12 runs for 8 factors).

- Parallel Execution: Prepare formulations using automated liquid/powder handling.

- Rapid Analysis: Employ parallel dissolution, micro-calorimetry, and spectroscopic stability assays.

- Data Analysis & Refinement: Use statistical models to identify critical factors. Refine using a response surface methodology (RSM) or subsequent simplex to pinpoint optimum.

Visualizing Pathways and Workflows

Diagram Title: Drug Development Pipeline with Risk Zones

Diagram Title: Simplex Optimization Algorithm Workflow

Diagram Title: CQA Control Across Pharmaceutical Development

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for EVOP & Development Experiments

| Reagent / Material | Function in Development | Specific Application Example |

|---|---|---|

| High-Throughput Screening Assay Kits (e.g., kinase, CYP450) | Early assessment of biological activity and off-target interactions. | Prioritizing lead compounds with optimal efficacy/safety profiles in in vitro models. |

| ADMET Prediction Software & Services (In silico & in vitro) | Predicting pharmacokinetics and toxicity before in vivo studies. | Reducing late-stage attrition due to poor PK or toxicity; guiding structural modification. |

| Design of Experiment (DoE) Software (e.g., JMP, MODDE) | Statistically designing efficient experiments and analyzing complex multivariate data. | Planning simplex or response surface experiments to optimize processes with minimal runs. |

| Stable-Isotope Labeled Standards | Enabling precise quantification of drugs and metabolites in complex biological matrices. | Developing robust PK/PD assays and meeting regulatory bioanalytical method validation requirements. |

| Artificial Stomach/Intestinal Fluids (Biorelevant media) | Predicting in vivo dissolution and absorption behavior of formulations. | Screening solid oral dosage forms for bioavailability risks during early development. |

| Forced Degradation Study Kits | Identifying potential degradation pathways and impurities of the API and formulation. | Establishing stability-indicating methods and defining the formulation design space for shelf life. |

An In-depth Technical Guide in the Context of EVOP Simplex Process Improvement Research

1. Introduction This technical guide details the core terminology and operational mechanics of the Evolutionary Operation (EVOP) simplex method, a statistical technique for continuous process improvement. Within pharmaceutical development, EVOP provides a structured, iterative approach for optimizing complex processes—such as bioreactor conditions, crystallization, or formulation—where small, planned variations are introduced to a running process to efficiently locate optimal operating conditions. The method hinges on the precise definition and manipulation of Response Variables, Factors, Vertices, and Movement Rules.

2. Core Terminology & Quantitative Framework

2.1 Response Variable (Y) The measured output used to judge process performance. In drug development, this is typically a Critical Quality Attribute (CQA). Examples: Product yield (%), impurity level (ppm), dissolution rate (%/hr), particle size (μm), biological potency (IU/mg).

2.2 Factors (X₁, X₂, ... Xₖ) The independent input process variables deliberately varied during the EVOP cycle. Factors are selected based on prior risk assessment (e.g., QbD principles). Examples: Temperature (°C), pH, agitation rate (RPM), feed rate (mL/min), catalyst concentration (mM).

2.3 Vertices The specific set of factor-level combinations that form the geometric simplex in the experimental design. For k factors, a simplex has k+1 vertices.

2.4 Movement Rules The algorithmic rules that determine the next simplex vertex to test based on the comparison of response variable values at the current vertices. The primary rule is the Reflection of the worst vertex through the centroid of the remaining vertices.

Table 1: Summary of Core Simplex EVOP Terminology and Typical Pharmaceutical Ranges

| Term | Symbol | Definition | Typical Pharmaceutical Context & Ranges |

|---|---|---|---|

| Response Variable | Y | Measured process output/CQA | Yield: 70-95%; Impurity A: 0.1-2.0%; Mean Particle Size: 50-200 μm |

| Factor | Xᵢ | Controlled process input | Temperature: 20-40°C; pH: 6.0-7.5; Agitation: 100-500 RPM |

| Vertex | Vⱼ | A specific combination of factor levels | e.g., V₁: (25°C, pH 6.5, 200 RPM) |

| Simplex | S | Geometric figure of k+1 vertices in k-dimensional space | A triangle for 2 factors; a tetrahedron for 3 factors. |

| Worst Vertex | V_w | Vertex yielding the least desirable response | e.g., Lowest yield, highest impurity. |

| Centroid | V₀ | Average coordinates of all vertices except V_w | Calculated point for reflection. |

3. Experimental Protocol: A Standard Simplex EVOP Cycle

- Step 1 – Initial Simplex Design: For k factors, establish an initial simplex of k+1 distinct operating conditions (vertices). A common method is to use a starting vertex (baseline process) and generate others by applying a step size (Δ) to each factor sequentially.

- Step 2 – Experimentation & Data Collection: Run the process at each vertex condition, ideally in a randomized order to mitigate noise. Measure the predefined response variable(s) with appropriate analytical methods (e.g., HPLC, bioassay).

- Step 3 – Statistical Analysis & Ranking: Calculate the mean response for each vertex. Rank vertices from best (e.g., highest yield) to worst (e.g., lowest yield).

- Step 4 – Apply Movement Rule (Reflection):

- Calculate the centroid (V₀) of all vertices excluding the worst vertex (Vw).

- Generate the new candidate vertex (Vr) via reflection: Vr = V₀ + α(V₀ - Vw), where the reflection coefficient α is typically 1.0.

- Perform confirmation run at V_r and measure the response.

- Step 5 – Iterate & Converge: Based on the response at V_r, the simplex expands, contracts, or continues reflecting to climb towards the optimum. The procedure terminates when no further improvement is observed or the optimum is satisfactorily located.

4. Visualizing the Simplex EVOP Algorithm

Diagram 1: Sequential logic of the simplex EVOP algorithm (73 chars)

Diagram 2: Geometry of a 2-factor simplex reflection move (58 chars)

5. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents & Materials for EVOP in Pharmaceutical Development

| Item / Solution | Function / Relevance in EVOP Studies |

|---|---|

| Designated Cell Culture Media / Feed | Consistent, chemically defined medium is critical for varying factors like nutrient concentration reliably in bioreactor EVOP. |

| Process Analytical Technology (PAT) Probes (e.g., pH, dO₂, Raman) | Enable real-time, in-line monitoring of factors and responses, providing high-frequency data for vertex characterization. |

| Reference Standards & Calibrants | Essential for validating analytical methods (e.g., HPLC, LC-MS) used to measure response variables (potency, impurities). |

| Buffering Agents & pH Modifiers | Allow precise control and variation of pH as a key factor in formulation or purification EVOP studies. |

| Catalysts / Enzymes (Standardized Activity) | Used as a variable factor (concentration) in synthetic route optimization; batch-to-batch consistency is paramount. |

| Surfactants & Excipients (GRAS) | Key variable factors in formulation EVOP for optimizing stability, dissolution, or bioavailability of the drug product. |

| High-Purity Solvents & Reagents | Minimize extrinsic noise by ensuring that variation in response is due to changed factors, not raw material variability. |

| Statistical Process Control (SPC) Software | Required for designing the simplex, randomizing runs, analyzing response data, and calculating new vertex coordinates. |

Implementing EVOP Simplex: A Step-by-Step Framework for Drug Development

Evolutionary Operation (EVOP) using the simplex method is a sequential, model-free optimization technique ideal for process improvement in regulated environments like pharmaceutical development. Its primary advantage is the ability to refine processes with minimal risk to product quality. This phase is foundational, determining the success or failure of the entire optimization sequence. Poor factor selection or improper level setting leads to inefficient exploration of the design space, wasted resources, and inconclusive results.

Defining the Optimization Objective & Response Selection

The objective must be quantifiable, aligned with Critical Quality Attributes (CQAs), and sensitive to factor changes. In drug development, multiple, often conflicting, responses are common (e.g., yield vs. purity). A primary response for guiding the simplex must be selected.

Table 1: Common Optimization Responses in Pharmaceutical Processes

| Response Variable | Typical Measurement Method | Justification for EVOP | Potential Conflict |

|---|---|---|---|

| Product Yield (%) | HPLC, UV-Vis Spectrophotometry | Directly impacts cost and efficiency. | May conflict with purity. |

| Impurity Level (%) | HPLC, LC-MS | Critical for safety and regulatory approval. | Optimization may reduce yield. |

| Process Time (hr) | In-line monitoring, batch records | Affects throughput and operational cost. | Shorter times may impact yield/purity. |

| Particle Size (µm) | Laser Diffraction, Microscopy | Critical for dissolution and bioavailability. | May be insensitive to some factors. |

Protocol for Primary Response Selection:

- Identify all Potential CQAs: From prior knowledge and Quality by Design (QbD) principles.

- Assay Qualification: Ensure measurement systems are validated (precision, accuracy, linearity).

- Perform Screening DOE: A Plackett-Burman or fractional factorial design to gauge each response's sensitivity to a broad set of potential factors.

- Calculate Signal-to-Noise Ratio: For each response

R, estimate(ΔR / σ_R)whereΔRis the range ofRin screening andσ_Ris measurement noise. The response with the highest ratio is often the best primary guide. - Define a Desirability Function: If multiple responses must be combined, use a Derringer-Suich desirability function to create a single composite response.

Systematic Factor Identification and Screening

The initial pool of potential factors (process parameters, material attributes) is typically large. A structured approach to reduce this to the vital few (2-4) for the initial simplex is required.

Table 2: Factor Screening Analysis (Hypothetical API Reaction Step)

| Potential Factor | Baseline Level | Test Range | P-Value (from Screening DOE) | Effect on Yield | Selected for Initial Simplex? |

|---|---|---|---|---|---|

| Reaction Temperature (°C) | 70 | 60 - 80 | 0.002 | Strong Positive | Yes (High Impact) |

| Catalyst Equivalents | 1.0 | 0.8 - 1.2 | 0.015 | Moderate Positive | Yes (Controllable) |

| Stirring Rate (RPM) | 500 | 300 - 700 | 0.450 | Negligible | No |

| Solvent Ratio (Water:MeOH) | 3:1 | 2:1 - 4:1 | 0.032 | Moderate Curvilinear | Yes (Suspected Optimum) |

| Addition Time (min) | 60 | 30 - 90 | 0.120 | Weak Negative | No (Hold Constant) |

Experimental Protocol for Definitive Screening:

- Literature & Risk Assessment: Compile potential factors from prior art (e.g., reaction mechanism) and risk tools (e.g., Fishbone diagram).

- Define Feasible Ranges: Based on equipment limits, safety, and solubility.

- Execute a Definitive Screening Design (DSD): A highly efficient 3-level design that identifies main effects and significant curvatures with few runs.

- Statistical Analysis: Fit a linear model. Factors with p-values < 0.1 (or a pre-defined significance level) and large effect sizes are shortlisted.

- Expert Review: A cross-functional team (Process Chemistry, Engineering, Analytics) must review statistical shortlists for practical relevance.

Setting Factor Levels & Initial Simplex Geometry

For k selected factors, the initial simplex is a k+1 vertex geometric figure. Level setting defines the size and orientation of this simplex in the design space.

Protocol for Determining Initial Factor Levels (Step Size):

- Establish the Vertex 0 (Baseline): A proven, stable operating condition.

- Define Step Size (Δ): For each factor

i, the step sizeΔ_ishould be large enough to produce a detectable change in the response (greater than 2x the measurement noise) but not so large as to immediately exit the feasible region.- Formula:

Δ_i = (Practical Upper Limit - Baseline) / N, whereNis typically between 5 and 10, providing 5-10 steps to the boundary.

- Formula:

- Construct the Initial Simplex: Using the standardized method, Vertex 0 is the baseline. Vertex

j(for j=1 to k) is created by adding the step sizeΔ_jto the baseline for factorj, while keeping all other factors at their baseline value.

Table 3: Initial Simplex Vertex Construction (k=3 factors)

| Vertex | Temperature (°C) | Catalyst (equiv.) | Solvent Ratio | Calculation Basis |

|---|---|---|---|---|

| V0 (Baseline) | 70 | 1.0 | 3:1 | Proven condition |

| V1 | 75 (+Δ_T) | 1.0 | 3:1 | V0 + Step for Factor 1 |

| V2 | 70 | 1.15 (+Δ_C) | 3:1 | V0 + Step for Factor 2 |

| V3 | 70 | 1.0 | 3.5:1 (+Δ_S) | V0 + Step for Factor 3 |

Diagram 1: Initial Simplex for 3 Factors (Width: 760px)

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for EVOP Pre-Planning & Screening

| Item / Solution | Function in Pre-Experimental Phase | Example Product/Category |

|---|---|---|

| Defined Chemical Substrates & Reagents | To ensure reproducibility. High-purity, well-characterized starting materials are non-negotiable. | Pharmacopoeial standards (USP, Ph. Eur.), certified reference materials (CRMs). |

| In-process Analytical Standards | For qualifying measurement systems and quantifying responses (yield, impurities) during screening. | Certified impurity standards, stable isotope-labeled internal standards for LC-MS. |

| Design of Experiment (DOE) Software | To generate statistically sound screening designs (Plackett-Burman, DSD) and analyze factor significance. | JMP, Modde, Design-Expert, or open-source R packages (rsm, DoE.base). |

| Process Analytical Technology (PAT) Probes | For real-time, non-destructive measurement of responses (e.g., concentration, particle size), enabling richer data. | In-line FTIR, FBRM (Focused Beam Reflectance Measurement), Raman probes. |

| Lab Execution System (LES) / Electronic Lab Notebook (ELN) | To meticulously record factor settings, environmental conditions, and raw response data, ensuring data integrity. | Benchling, LabWare LES, Dotmatics. |

| Statistical Analysis Software | To perform power analysis, calculate effect sizes, signal-to-noise ratios, and fit preliminary models. | SAS, R, Python (with SciPy, statsmodels libraries). |

Within the broader thesis on the application of Evolutionary Operation (EVOP) simplex methodology for pharmaceutical process improvement, the construction of the initial simplex is a critical first-order determinant of success. For researchers and drug development professionals, this step establishes the foundational search space from which a process is methodically perturbed and optimized. The initial simplex's size dictates the magnitude of the initial exploration step, balancing between coarse screening and the risk of moving into undesirable or non-representative operational regions. Its orientation in the experimental factor space can significantly influence the trajectory and efficiency of the subsequent sequential simplex algorithm, impacting the number of experimental runs required to converge on an optimum. In drug development, where materials are often scarce and costly (e.g., active pharmaceutical ingredients, custom ligands), and processes must be robust for scale-up, a scientifically-principled initialization is not merely academic but a practical necessity for efficient resource utilization.

Foundational Theory: Geometry of the Simplex

In an n-dimensional factor space, a simplex is a geometric figure defined by n+1 vertices. For two factors, it is a triangle; for three, a tetrahedron. The EVOP simplex method operates by comparing responses at these vertices, moving away from the worst-performing point, and iteratively reflecting, expanding, or contracting the simplex to climb the response surface toward an optimum.

The two paramount decisions in its construction are:

- Size (∆): The step size or initial perturbation for each factor from a chosen baseline point (often the current operating conditions).

- Orientation: The alignment of the simplex in the factor space, determined by the relative scaling of factors and the initial step direction matrix.

Quantitative Guidelines for Determining Initial Size (∆)

The choice of initial step size is context-dependent, balancing statistical detectability against practical and economic constraints. The following table synthesizes current recommendations from literature and industry practice for pharmaceutical applications.

Table 1: Guidelines for Initial Simplex Step Size Selection

| Factor Type / Consideration | Recommended Step Size (∆) | Rationale & Protocol Reference |

|---|---|---|

| Process Factors (e.g., Temp, pH, Flow Rate) | 10-20% of the chosen experimental range or known safe operating window. | Ensures the perturbation is large enough to produce a measurable effect above baseline noise but remains within feasible and safe bounds. |

| Formulation Factors (e.g., Excipient Ratio) | 0.5-2.0% w/w or v/v from target, depending on criticality. | For low-dose drug products or sensitive formulations, smaller steps prevent exceeding design space boundaries or causing stability issues. |

| Analytical/Assay Factors (e.g., Mobile Phase %B) | As defined by a preliminary univariate scouting experiment. | Protocol: Conduct a short gradient scouting run (e.g., 5-95% B over 20 min) to identify the region where the analyte elutes. Set ∆ to cover a change that shifts retention time by 0.5-1.0 min. |

| Statistical Power Basis | ∆ ≥ (2 * σ / b), where σ is estimated std. error, b is slope estimate. | Derived from power analysis. Protocol: Run 4-6 center point replicates at baseline to estimate σ. Use prior knowledge or a preliminary factorial screen to estimate linear coefficient (b) for each factor. |

| Resource-Limited Context | Larger ∆ to identify promising region quickly, followed by refinement. | When API or reagents are extremely limited, a larger initial step may be used in a screening mode to identify a promising direction before switching to a smaller, refined simplex. |

Methodologies for Establishing Initial Orientation

Orientation is governed by the scaling of factors and the construction of the initial vertex matrix. Poor scaling (e.g., temperature in °C vs. pressure in kPa) can distort the simplex, making it elongated and less efficient.

Protocol 4.1: Factor Scaling for Balanced Orientation

- Define the high (+1) and low (-1) bounds for each of the n independent factors based on the known operating region or design space.

- For each factor, calculate the step size in engineering units using Table 1 guidelines (e.g., ∆_temp = 5°C).

- Compute the scaled step size: pi = ∆i / (Highi - Lowi). This p_i value represents the step in coded units (approximately).

- Construct the initial simplex vertices. Starting from the baseline point x₀, the other n vertices (x₁...xₙ) are generated. A common and computationally convenient orientation is given by:

- xᵢ = x₀ + pi * ei for i = 1...k-1

- xᵢ = x₀ - (p1 + ... + p{k-1}) * ei for i = k, where k is a chosen factor index. Where ei is the unit vector for factor i. This creates a right-angle simplex aligned with the factor axes.

Protocol 4.2: Incorporating Process Knowledge for Non-Standard Orientation If process knowledge suggests the optimum lies along a specific diagonal direction (e.g., increasing Temp and decreasing Time together), the initial simplex can be rotated to align an edge with this direction.

- Define the preferred direction vector d in coded units.

- Normalize d to length equal to the average desired step size.

- Use d as the first edge from the baseline. Generate remaining vertices using an orthogonalization procedure (e.g., Gram-Schmidt) to create a regular simplex oriented along d.

Experimental Validation Protocol for Initial Simplex Parameters

Prior to committing to a full EVOP study, a preliminary experiment can validate the chosen size and orientation.

Protocol 5.1: Center Point & Star-point Check

- Run m replicates (m ≥ 3) at the chosen baseline center point x₀.

- Run single experiments at each of the n+1 proposed initial simplex vertices.

- Analysis: Calculate the mean response at x₀ and the standard deviation (σ). Compare responses at vertices. The difference between the best and worst vertex responses should be significantly larger than the noise level (e.g., > 3σ). If not, consider increasing ∆. Assess if the response pattern matches expected process knowledge; if not, re-evaluate factor scaling or orientation.

Visualizing Simplex Construction & Evolution

Simplex Construction and First Step Workflow

EVOP Sequential Simplex Decision Logic

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 2: Essential Research Toolkit for Simplex-Based Process Optimization

| Item / Solution | Function in EVOP Simplex Studies | Example/Note |

|---|---|---|

| High-Throughput Screening (HTS) Microplates & Liquid Handlers | Enables rapid, parallel preparation of initial simplex vertices and subsequent experimental conditions, crucial for resource-intensive biomolecular assays or formulation screenings. | 96-well or 384-well plates. Automated dispensers ensure precise factor level adjustments (e.g., varying buffer salt concentration). |

| Process Analytical Technology (PAT) Probes | Provides real-time, in-situ response measurements (e.g., pH, Dissolved O₂, Particle Size via FBRM, Concentration via FTIR) for immediate evaluation after each simplex move, accelerating cycles. | Critical for bioprocess optimization (fermentation, cell culture) where offline assays are slow. |

| Design of Experiments (DOE) Software | Used to design the initial simplex, scale factors, randomize run order, visualize the simplex in factor space, and track the evolutionary path. Essential for analysis and documentation. | JMP, Design-Expert, or custom R/Python scripts (scipy.spatial, pyDOE2 packages). |

| Structured Experiment Log (Electronic Lab Notebook - ELN) | Mandatory for meticulously recording the conditions of each vertex (factor levels), the measured response(s), and the decision (reflect/expand/contract) for each step. Ensures traceability and reproducibility. | Must be configured with specific templates for simplex EVOP studies. |

| Calibrated Reference Standards | For analytical method optimization simplexes, stable reference materials are needed to generate a consistent, reliable response (e.g., chromatographic peak area, assay signal) at every new vertex condition. | Certified API or impurity standards for HPLC method development. |

| Modular, Bench-Scale Reactor Systems | For chemical process optimization, systems that allow precise, automated control of factors like temperature, stirring speed, and reagent addition rates are needed to faithfully reproduce each proposed simplex vertex condition. | Enables accurate scale-down modeling of manufacturing processes. |

Within the domain of pharmaceutical process optimization, Evolutionary Operation (EVOP) simplex methods provide a robust statistical framework for process improvement with minimal disruption to production runs. This whitepates the core operational engine for implementing EVOP simplex strategies in drug development. The RERM framework formalizes the iterative, data-driven decision-making cycle essential for navigating the simplex geometry, where each phase—Run (conducting a designed experiment), Evaluate (analyzing response data), Reflect (interpreting results against hypotheses and constraints), and Move (calculating and implementing the next simplex vertex)—constitutes one learning iteration. This guide details the technical execution of this cycle within a contemporary research and development (R&D) context.

The RERM Framework: A Technical Deconstruction

Phase 1: RUN

This phase involves executing a small, designed experiment at the vertices of the current simplex. For a process with n critical process parameters (CPPs), the simplex consists of n+1 experimental runs.

- Experimental Protocol for a Simplex Run:

- Define the Simplex: Identify the current simplex vertices in the CPP space. Each vertex is a specific setpoint combination of CPPs (e.g., Reaction Temperature, pH, Catalyst Concentration).

- Randomize Order: To mitigate confounding from lurking variables, randomize the run order of the n+1 experiments.

- Execute Under Control: Conduct each run under strict Good Laboratory Practice (GLP) or Quality by Design (QbD) principles, maintaining control over all non-CPPs.

- Measure Critical Quality Attributes (CQAs): For each run, quantify pre-defined multi-variate responses (e.g., yield, impurity profile, particle size distribution).

Phase 2: EVALUATE

Responses from the RUN phase are statistically analyzed to identify the worst-performing vertex.

- Methodology:

- Data Normalization: Normalize each CQA response to a common scale (e.g., 0-1) based on pre-defined specification limits or ideal targets.

- Desirability Function Application: Apply a multi-response desirability function (e.g., Derringer-Suich) to aggregate normalized CQAs into a single Composite Desirability Index (D) for each vertex.

- Statistical Comparison: Perform analysis of variance (ANOVA) or calculate confidence intervals around the mean D for each vertex to account for experimental error. The vertex with the lowest statistically significant D is identified as the "worst" point.

Table 1: Example Evaluation of a 2-Factor Simplex (Temperature, pH)

| Simplex Vertex (Temp, pH) | Yield (%) | Impurity A (%) | Desirability (Yield) | Desirability (Impurity) | Composite Desirability (D) |

|---|---|---|---|---|---|

| V1 (70°C, 6.0) | 85.2 | 1.5 | 0.85 | 0.70 | 0.77 |

| V2 (75°C, 5.8) | 88.7 | 0.9 | 0.95 | 0.95 | 0.95 |

| V3 (72°C, 6.2) | 82.1 | 2.1 | 0.78 | 0.50 | 0.62 |

| Conclusion | V3 is the worst vertex. |

Phase 3: REFLECT

This phase involves strategic reasoning before action. Researchers must interpret the Evaluate output within the broader experimental and regulatory landscape.

- Key Reflection Questions:

- Convergence: Has the simplex area reduced below a pre-set threshold, indicating a potential optimum?

- Constraint Violation: Does the proposed new move violate any hard process constraints (e.g., solvent boiling point, stability limit)?

- Ridge Detection: Is the simplex oscillating, suggesting movement along a response ridge?

- Practical Significance: Is the improvement in D from the proposed move greater than the noise level and practically meaningful for the process?

Phase 4: MOVE

The simplex is progressed by rejecting the worst point and replacing it with a new vertex through geometric reflection.

- Algorithm:

- Calculate the centroid (C) of all vertices excluding the worst vertex (V~worst~).

- Generate the new vertex (V~new~) via reflection: V~new~ = C + α(C - V~worst~), where the reflection coefficient α is typically 1.0.

- If V~new~ is worse than V~worst~, apply contraction or reduction rules per the Nelder-Mead simplex logic.

- The new simplex for the next RERM cycle consists of the retained vertices and V~new~.

Title: The RERM Cycle Logic Flow

Title: Geometric Move in Simplex EVOP

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for RERM-Driven Process Optimization

| Item | Function in RERM Context |

|---|---|

| Design of Experiment (DoE) Software (e.g., JMP, Design-Expert) | Facilitates simplex initialization, run randomization, and advanced statistical analysis during the Evaluate phase. |

| Process Analytical Technology (PAT) Probes (e.g., FTIR, FBRM) | Enables real-time, in-line measurement of CQAs, providing rich data streams for instantaneous Evaluation. |

| High-Throughput Experimentation (HTE) Robotic Platforms | Automates the Run phase, allowing rapid, parallel execution of simplex vertices with high precision and reproducibility. |

| Laboratory Information Management System (LIMS) | Tracks all experimental metadata, reagent batches, and raw data, providing the audit trail essential for Reflection and regulatory compliance. |

| Stable Isotope-Labeled Analytical Standards | Critical for developing precise and accurate bioanalytical methods used to quantify complex CQAs like metabolite profiles during Evaluation. |

| Advanced Chemometric Software | Used to model complex, non-linear response surfaces, aiding in the interpretation of simplex behavior during Reflect and Move. |

Advanced Protocol: Integrating RERM with a Model-Informed Approach

Title: Protocol for a RERM Cycle Augmented by Bayesian Optimization.

Objective: To enhance the efficiency of the simplex Move by incorporating a probabilistic surrogate model.

Methodology:

- Initialization: Perform 2-3 classic RERM cycles to gather initial data.

- Surrogate Modeling (Enhanced Evaluate): After each RUN, fit a Gaussian Process (GP) regression model to all historical data (CQAs vs. CPPs).

- Acquisition Function (Enhanced Reflect & Move): Instead of simple geometric reflection, calculate the next vertex by maximizing an Acquisition Function (e.g., Expected Improvement, EI) using the GP model. EI balances exploitation (moving toward high predicted desirability) and exploration (probing regions of high uncertainty).

- Iteration: Run the experiment at the EI-proposed vertex and repeat from Step 2.

This hybrid protocol accelerates convergence, especially for noisy or resource-intensive processes typical in late-stage drug development.

Evolutionary Operation (EVOP) using the simplex method is a systematic, iterative strategy for process improvement, designed to move a system toward an optimum with minimal risk and resource expenditure. This whitepaper presents a case study in pharmaceutical formulation optimization, framed explicitly as a practical application within a broader thesis on Simplex EVOP for continuous process improvement in drug development. We demonstrate how the modified simplex algorithm guides the sequential, data-driven adjustment of critical formulation variables to simultaneously optimize tablet hardness and dissolution profile—two often antagonistic Critical Quality Attributes (CQAs).

Core Experimental Methodology: Simplex EVOP Protocol

The following protocol outlines the stepwise application of a modified simplex method for formulation optimization.

2.1 Pre-Experimental Setup

- Define Response Variables: Identify Tablet Hardness (N) and Dissolution at 30 minutes (%Q30) as primary CQAs.

- Define Controlled Factors: Select two independent, continuous formulation variables: Microcrystalline Cellulose (MCC) to Lactose Ratio (X1) and Magnesium Stearate (MgSt) Concentration (X2).

- Define Constraints: Establish acceptable ranges: X1 (0.2 to 0.8), X2 (0.5% to 2.0% w/w). All other formulation components and processing parameters (e.g., granulation time, compression force) are held constant.

- Design Initial Simplex: A geometric figure with k+1 vertices, where k is the number of factors. For 2 factors, the simplex is a triangle.

2.2 Iterative Experimental Cycle

- Run Experiments: Prepare and evaluate formulations corresponding to the current simplex vertices (e.g., 3 formulations per cycle).

- Measure Responses: For each batch, measure mean tablet hardness (n=10) and dissolution %Q30 (n=6).

- Calculate Composite Desirability (D): Transform each response into an individual desirability (d) and combine geometrically. Target: Maximize D.

- d(Hardness) defined as: >50N = 1, <30N = 0, with linear ramp.

- d(%Q30) defined as: >80% = 1, <60% = 0, with linear ramp.

- Composite: D = √(d(Hardness) * d(%Q30))

- Apply Simplex Rules:

- Rank Vertices: Identify the Worst (W), Next Worst (N), and Best (B) based on D.

- Reflection: Calculate the Reflected (R) point: R = P + α(P - W), where P is the centroid of all vertices except W, and α (reflection coefficient) = 1.0.

- Evaluation: Run experiment at R.

- Decision Logic:

- If R > B, test Expansion (E): E = P + γ(R - P), γ=2.0.

- If R is between B and N, accept R as new vertex.

- If R < N, test Contraction: either outside (Cout) or inside (Cin).

- If R < W, perform Shrinkage towards B.

- Form New Simplex: Replace W with the accepted new vertex, forming a new triangle.

- Check Convergence: Terminate when the simplex size shrinks below a predefined threshold or a preset maximum D is achieved.

Data Presentation: Simplex EVOP Optimization Cycles

Table 1: Initial Simplex (Cycle 0) and Response Data

| Vertex ID | MCC:Lactose (X1) | MgSt (%) (X2) | Hardness (N) | Dissolution %Q30 | Desirability (d_H) | Desirability (d_D) | Composite (D) |

|---|---|---|---|---|---|---|---|

| V1 (W) | 0.2 | 0.5 | 32.1 | 92.5 | 0.105 | 1.000 | 0.324 |

| V2 (B) | 0.5 | 1.25 | 41.5 | 78.3 | 0.575 | 0.915 | 0.726 |

| V3 (N) | 0.8 | 2.0 | 48.9 | 65.0 | 0.945 | 0.250 | 0.486 |

Table 2: Optimization Path Through Sequential Simplex Cycles

| Cycle | Vertex Action | X1 | X2 | Hardness (N) | Dissolution %Q30 | Composite (D) |

|---|---|---|---|---|---|---|

| 1 | Reflected (R) | 0.74 | 0.5 | 46.2 | 85.1 | 0.825 |

| 2 | Expanded (E) | 0.92 | 0.125 | 39.8 | 88.7 | 0.749 |

| 3 | Reflected (R) | 0.65 | 1.06 | 43.5 | 81.4 | 0.863 |

| 4 | Contracted (Cin) | 0.68 | 1.16 | 44.1 | 79.9 | 0.851 |

| 5 | Reflected (R) - OPTIMUM | 0.61 | 0.95 | 42.0 | 83.2 | 0.894 |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Formulation Optimization Studies

| Item / Reagent | Function & Rationale in Optimization |

|---|---|

| Microcrystalline Cellulose (MCC) | Diluent/Binder: Provides compressibility and tablet hardness. Varying its ratio to lactose is a key factor for mechanical strength optimization. |

| Lactose Monohydrate | Soluble Diluent: Enhances dissolution rate. Its ratio to MCC allows balancing hardness (from MCC) and dissolution (from lactose). |

| Magnesium Stearate | Lubricant: Reduces friction during ejection. Critical low-concentration factor; over-lubrication can negatively impact hardness and dissolution. |

| Active Pharmaceutical Ingredient (API) | Model Drug: A BCS Class II drug (low solubility, high permeability) is often used to make dissolution a critical, optimizable response. |

| Croscarmellose Sodium | Disintegrant: Promotes tablet breakup in dissolution media, a critical factor for achieving target %Q30. Often held at a constant, optimal level. |

| Dissolution Media Buffer (e.g., pH 6.8 Phosphate) | Test Medium: Simulates intestinal fluid. Standardized media is required for reproducible, discriminatory dissolution testing. |

| Simplex EVOP Software (e.g., JMP, Design-Expert, custom Python/R scripts) | Algorithm Execution: Facilitates the automatic calculation of centroid, reflection, expansion points, and tracks the simplex progression. |

Visualization of the Simplex EVOP Workflow and Decision Logic

Diagram 1: Simplex EVOP Iterative Optimization Algorithm (86 chars)

Diagram 2: Cycle 0 Simplex Geometry & Reflection (87 chars)

1. Introduction

This article presents a technical case study within the broader thesis that Evolutionary Operation (EVOP) and the Simplex method provide a robust, systematic framework for continuous process improvement in biopharmaceutical development. Specifically, we focus on the optimization of a chemically defined feed media for a Chinese Hamster Ovary (CHO) cell culture process producing a monoclonal antibody (mAb). The goal is to enhance process yield—measured as volumetric productivity (titer)—while maintaining critical quality attributes (CQAs) of the product. Traditional one-factor-at-a-time (OFAT) approaches are inefficient for navigating the complex, interactive effects of media components. This case study demonstrates the application of a sequential simplex EVOP strategy to efficiently identify an optimal formulation.

2. Methodology: Sequential Simplex EVOP Protocol

The experiment employed a modified simplex method for optimization. The response variable was the integrated viable cell density (IVCD, in 10^9 cell-days/L) and the final titer (g/L). CQAs (aggregate percentage, charge variants) were monitored as constraints.

2.1 Initial Simplex Formation

- Factors: Three key media components identified from prior screening as having significant interaction effects were selected for optimization:

- Glutamine (Gln): Energy and nitrogen source.

- Choline Chloride (Cho): Precursor for phospholipid synthesis.

- Amino Acid Complex (AA): A balanced group of 6 essential amino acids.

- Baseline: A standard commercial feed formulation served as the baseline (Vertex 0).

- Step Size: 15% variation from the baseline concentration for each factor was chosen based on prior knowledge of operational ranges.

- Initial Vertices: Four experimental conditions (including baseline) were calculated to form an initial simplex in the three-dimensional factor space.

2.2 Experimental Execution (Per Cycle)

- Setup: CHO cells (clone expressing a model IgG1 mAb) were inoculated in 250 mL shake flasks (working volume 50 mL) with seeding density of 0.3 x 10^6 cells/mL in standard basal media (n=3 per condition).

- Feeding: A fed-batch process was initiated on day 3. The experimental feed formulations, as defined by the simplex vertices, were administered according to a pre-determined feeding strategy (5% v/v daily from day 3 to day 7).

- Monitoring: Cultures were maintained for 14 days. Samples were taken every other day for:

- Cell count and viability (via trypan blue exclusion).

- Metabolite analysis (Glucose, Lactate, Ammonia via bioanalyzer).

- Titer measurement (Protein A HPLC).

- Endpoint Analysis: On day 14, harvest samples were analyzed for CQAs: size-exclusion chromatography (SEC-HPLC) for aggregates, and cation-exchange chromatography (CEX-HPLC) for charge variants.

2.3 Simplex Evolution Rules After each experimental cycle, the responses for all vertices were ranked. The algorithm proceeded as follows:

- Reflection: The vertex with the worst product of titer and IVCD was reflected through the centroid of the remaining vertices to generate a new candidate point.

- Expansion: If the reflected point yielded the best response so far, an expansion point was tested.

- Contraction: If the reflected point was worse than the second-worst point, a contraction point was tested.

- Shrinkage: If the worst vertex persisted after several iterations, the simplex was shrunk towards the best vertex.

- Constraint Handling: Any formulation resulting in aggregate levels >2.0% or a significant shift in main peak charge variant was considered "worse" regardless of titer, ensuring CQA constraints were not violated.

3. Results & Data Summary

After five sequential simplex cycles (20 unique experimental conditions), an optimum region was identified. Key data from the baseline, worst vertex of cycle 1, and the optimized vertex from cycle 5 are summarized below.

Table 1: Performance Metrics of Selected Simplex Vertices

| Vertex Description | [Gln] (mM) | [Cho] (µM) | [AA] (Relative %) | Final Titer (g/L) | IVCD (10^9 cell-days/L) | Aggregates (%) | Viability at Day 14 (%) |

|---|---|---|---|---|---|---|---|

| Baseline (Start) | 20.0 | 150 | 100 | 3.5 | 8.2 | 1.2 | 78 |

| Cycle 1 Worst | 23.0 | 127.5 | 85 | 2.9 | 7.1 | 2.5* | 65 |

| Cycle 5 Optimized | 17.0 | 180 | 115 | 4.8 | 10.5 | 1.4 | 85 |

- CQA constraint violation.

Table 2: Key Metabolite Profiles at Harvest (Day 14)

| Vertex Description | Residual Glucose (g/L) | Lactate (g/L) | Ammonia (mM) | Specific Productivity (pg/cell/day) |

|---|---|---|---|---|

| Baseline (Start) | 2.1 | 1.5 | 4.2 | 42.7 |

| Cycle 1 Worst | 4.5 | 0.8 | 5.8 | 40.8 |

| Cycle 5 Optimized | 0.8 | 2.8 | 3.0 | 45.7 |

The optimized formulation reduced ammonia accumulation and improved glucose consumption efficiency, correlating with enhanced cell growth and productivity.

4. The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Cell Culture Media Optimization

| Item | Function / Relevance to Experiment |

|---|---|

| Chemically Defined Basal & Feed Media | Provides a consistent, animal-component-free foundation; enables precise modification of specific components. |

| Single-Component Stock Solutions (e.g., Glutamine, Choline, Amino Acids) | Allows for exact, independent adjustment of factor levels as dictated by the simplex algorithm. |

| Metabolite Analysis Kit (Bioanalyzer/Cedex) | For rapid, daily measurement of glucose, lactate, and ammonia to track metabolic shifts. |

| Automated Cell Counter (e.g., Vi-CELL, NucleoCounter) | Provides accurate and precise cell density and viability data for calculating IVCD. |

| Protein A HPLC Columns | For rapid and high-throughput titer measurement from cell culture supernatants. |

| SEC-HPLC & CEX-HPLC Columns | For analyzing critical quality attributes (aggregates and charge variants) to enforce optimization constraints. |

| DOE/Statistical Software (e.g., JMP, Design-Expert) | Used to design the initial simplex, visualize the factor space, and analyze response data. |

5. Visualizations

Simplex EVOP Workflow for Media Optimization

Media Component Impact on Cell Culture Outcomes

Advanced EVOP Simplex Strategies: Troubleshooting and Refining Your Optimization

Evolutionary Operation (EVOP) simplex methodology is a cornerstone of systematic process improvement in pharmaceutical development. It employs a geometric framework—typically a simplex—to iteratively navigate the experimental factor space toward optimal process conditions. However, the efficacy of this approach is critically undermined by two interrelated challenges: the presence of high-variance, noisy data inherent in complex biological systems, and the imposition of hard or soft constraints that define the feasible experimental region. This guide details the technical pitfalls arising from these challenges and provides robust protocols for mitigation, ensuring the reliability of optimization in drug development.

Quantifying the Impact: Noise and Constraints

The following table summarizes common sources of noise and types of experimental constraints, along with their typical impact on an EVOP simplex procedure.

Table 1: Characterization of Noise Sources and Experimental Constraints

| Category | Specific Type | Typical Source in Drug Development | Impact on Simplex Progression |

|---|---|---|---|

| Noise (Variance) | Analytical Variance | HPLC/MS potency assay, dissolution testing. | Obscures true direction of improvement; causes reflection to wrong vertex. |

| Biological Variance | Cell culture growth rates, in vivo animal model responses. | Increases required replicate number; reduces statistical power for vertex comparison. | |

| Process Variance | Solid dose blending uniformity, fermentation batch effects. | Can lead to pseudo-cycles or stagnation near an optimum. | |

| Constraints | Hard Boundary (Discontinuous) | Solubility limit, stable pH range, equipment physical limits. | Simplex can collapse or shrink prematurely if a vertex is invalid. |

| Soft Boundary (Penalty) | Impurity formation (increases beyond threshold), cost penalties. | Distorts the true response surface, leading to suboptimal convergence. | |

| Constrained Factor | Catalyst loading (≥ 0%), excipient ratio (must sum to 1). | Reduces the dimensionality of the free experimental region. |

Core Experimental Protocols for Mitigation

Protocol 1: Replication Strategy for Noise Reduction within a Simplex Cycle

Objective: To statistically distinguish between vertices despite inherent process and analytical noise.

Methodology:

- Initial Noise Assessment: Prior to main EVOP, perform a nested Gage R&R study at a center point to decompose total variance into analytical, batch-to-batch, and within-batch components.

- Adaptive Replication:

- Calculate the required number of replicates (n) per vertex for the next simplex cycle using an adaptive formula based on the estimated standard deviation (σ) from prior cycles and the minimum detectable effect (Δ) of practical importance:

n ≥ 2 * (t_α/2 + t_β)^2 * (σ/Δ)^2wheretare critical values from the t-distribution for desired α (Type I error) and β (Type II error) rates. - Implement sequential centroid replication: Allocate more replicates to the new vertex after a reflection operation and to the centroid point of the simplex, as these are critical for direction estimation.

- Calculate the required number of replicates (n) per vertex for the next simplex cycle using an adaptive formula based on the estimated standard deviation (σ) from prior cycles and the minimum detectable effect (Δ) of practical importance:

Protocol 2: Constrained Region Handling via Barrier Function Integration

Objective: To allow the simplex algorithm to operate effectively when vertices fall infeasible regions.

Methodology:

- Constraint Mapping: Define all constraints mathematically (e.g., [Reactant A] ≤ 2.0 mol%; [Byproduct] ≤ 0.5%).

- Apply a Logarithmic Barrier Function: Modify the primary response (e.g., yield) for optimization purposes when a vertex approaches a constraint.

- For a constraint

c(x) ≤ 0, the penalized responseP(x)becomes:P(x) = Primary_Response(x) - μ * Σ log(-c_i(x))whereμis a small, positive barrier parameter that is decreased over successive EVOP cycles.

- For a constraint

- Simplex Logic Adjustment: If a new vertex violates a hard constraint, do not accept it. Instead, execute a contraction towards the feasible centroid rather than a simple reflection, effectively "sliding" the simplex along the constraint boundary.

Visualizing the Interaction

Diagram 1: EVOP Simplex Modified for Noise & Constraints

Title: Modified EVOP Simplex Workflow with Noise and Constraint Handling

Diagram 2: Constraint Effect on Simplex Search Space

Title: Simplex Path Distortion Due to a Hard Constraint

The Scientist's Toolkit: Research Reagent & Solutions

Table 2: Essential Materials for Robust EVOP Studies

| Item | Function & Rationale |

|---|---|

| Internal Standard (Stable Isotope Labeled) | Normalizes for analytical variability in mass spectrometry, reducing noise in potency/impurity measurements. |

| Process Capability (Cp/Cpk) Reference Standard | A well-characterized material run with each batch to separate process shift from random noise. |

| Designated EVOP Software (e.g., JMP, MODDE, custom R/Python script) | Enables accurate calculation of penalized responses, simplex geometry, and statistical significance of vertex differences. |

| Barrier Function Parameter (μ) Schedule | A predefined protocol for reducing the penalty parameter, ensuring convergence to a true boundary optimum. |

| Nested ANOVA Software Module | Critical for initial noise decomposition to inform the replication strategy (Protocol 1). |

| Calibrated Process Analytical Technology (PAT) | In-line sensors (e.g., Raman, NIR) provide high-frequency data to average out within-batch noise. |

Within the broader thesis of Evolutionary Operation (EVOP) simplex methodology for pharmaceutical process optimization, the rules for reflection, expansion, and contraction form the algorithmic core for navigating the factor space towards an optimum. This guide details their technical application in drug development research.

Theoretical Framework within EVOP Simplex

The sequential simplex method is a gradient-free optimization algorithm ideal for experimental process improvement where the response surface is unknown. Given k process factors (e.g., temperature, pH, catalyst concentration), the simplex is a geometric figure of k+1 vertices. Each vertex represents a unique experimental condition, with its associated measured response (e.g., yield, purity, particle size). The algorithm iteratively moves the simplex away from poor performance towards the optimum by applying three core operations: Reflection, Expansion, and Contraction.

Formal Rules and Decision Logic

The algorithm's progression is governed by comparing responses at specific vertices. Let the vertices be sorted such that R(B) is the best response, R(W) is the worst response, and R(NW) is the next-worst response. The centroid P̄ is calculated from all vertices except W. The fundamental operations are:

- Reflection: Generate a new vertex R by reflecting W through the centroid: R = P̄ + α(P̄ - W), where α (reflection coefficient) is typically 1.0.

- Expansion: If the reflected vertex is better than the current best, explore further by generating an expansion vertex E: E = P̄ + γ(R - P̄), where γ (expansion coefficient) is typically 2.0.

- Contraction: If the reflected point is worse than or equal to the next-worst, the simplex contracts.

- Outside Contraction: If R is better than W but worse than or equal to NW, contract towards R: OC = P̄ + β(R - P̄), β (contraction coefficient) typically 0.5.

- Inside Contraction: If R is worse than W, contract away from W: IC = P̄ - β(P̄ - W).

The decision logic for applying these rules is summarized in Table 1 and visualized in Figure 1.

Table 1: Decision Logic for Simplex Operations

| Condition (Response Comparison) | Operation Performed | New Vertex to Evaluate |

|---|---|---|

| R(R) > R(B) | Expansion | E |

| R(B) ≥ R(R) > R(NW) | Reflection (Replace W with R) | R |

| R(NW) ≥ R(R) > R(W) | Outside Contraction | OC |

| R(R) ≤ R(W) | Inside Contraction | IC |

Figure 1: EVOP Simplex Algorithm Decision Workflow

Experimental Protocol for a Drug Synthesis Application

Objective: Optimize yield of active pharmaceutical ingredient (API) Intermediate X. Factors (k=2): Reaction Temperature (T, °C), Catalyst Equivalents (CatEq, mol%). Response: Isolated Yield (%).

Step 1: Initial Simplex Design. Define a starting vertex (V1) and step sizes (ΔT=5°C, ΔCatEq=0.2). A common initial simplex is constructed:

- V1: (T, CatEq) = (60, 1.0)

- V2: (T + 0.97ΔT, CatEq + 0.26ΔCatEq) = (64.85, 1.052)

- V3: (T + 0.26ΔT, CatEq + 0.97ΔCatEq) = (61.3, 1.194)

Step 2: Experimental Execution.

- Set up three parallel reaction vessels with conditions V1, V2, V3.

- Execute the synthesis of Intermediate X following standardized protocol (substrate charge, solvent volume, stirring rate, time).

- Quench, workup, and purify using identical techniques.

- Isolate product and determine exact mass and yield via quantitative HPLC against a calibrated standard.

Step 3: Ranking & Calculation. Results: R(V1)=72%, R(V2)=85%, R(V3)=68%. Therefore:

- B = V2 (85%), W = V3 (68%), NW = V1 (72%).

- Calculate P̄ from V1 and V2: P̄ = [(60+64.85)/2, (1.0+1.052)/2] = (62.43, 1.026)

Step 4: Apply Rules.

- Reflection: α=1. R = P̄ + (P̄ - W) = (62.43+(62.43-61.3), 1.026+(1.026-1.194)) = (63.56, 0.858).

- Experiment: Evaluate R(V4=R) -> Yield = 88%.

- Decision: R(R=88%) > R(B=85%) → EXPANSION.

- Expansion: γ=2. E = P̄ + 2(R - P̄) = (62.43+2(63.56-62.43), 1.026+2(0.858-1.026)) = (64.69, 0.690).

- Experiment: Evaluate V5=E -> Yield = 82%.

- Outcome: R(R=88%) is better than R(E=82%). Replace worst vertex (V3) with the reflected vertex (V4=R). New simplex is V1, V2, V4.

Step 5: Iterate. Continue until convergence (e.g., when step size falls below a threshold or responses stabilize across vertices).

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for EVOP Simplex Experiments in Process Chemistry

| Item | Function & Rationale |

|---|---|