The Secret Life of Goo

How Scientists at IC-RMM3 Are Decoding the Flow of Everything

Conference: 3rd International Conference on Rheology and Modeling of Materials

Article Navigation

Forget solid or liquid – the world is mostly weird stuff in between.

Your toothpaste stubbornly clinging to the brush, the ketchup that refuses to leave the bottle until you shake it violently, the molten glass being shaped into a delicate vase, the flexible screen on your phone bending without breaking – these are all governed by rheology, the science of how materials flow and deform. And recently, the brightest minds in this fascinating field converged at the 3rd International Conference on Rheology and Modeling of Materials (IC-RMM3) to share breakthroughs that are shaping our future, from advanced manufacturing to life-saving medical devices.

Why Rheology Rules Our World

Rheology isn't just about quirky fluids; it's fundamental to almost everything we make and use. Understanding how a material behaves under stress – whether it flows like honey, stretches like rubber, shatters like glass, or something more complex – is crucial:

Designing Better Products

Creating the perfect consistency for paints, foods, cosmetics, and pharmaceuticals.

Revolutionizing Manufacturing

Optimizing processes like 3D printing, injection molding, and metal forging.

Developing Advanced Materials

Engineering lightweight, strong composites for aerospace or flexible electronics.

Improving Medical Treatments

Designing injectable drug delivery systems or understanding blood flow dynamics.

At IC-RMM3, researchers combined cutting-edge experiments with sophisticated computer modeling to crack the code of complex materials, moving beyond simple labels to predict and control their behavior with unprecedented precision.

Spotlight: The Armor That Thickens on Impact

One standout presentation at IC-RMM3 showcased a revolutionary experiment blending rheology and materials science: the development of next-generation shear-thickening smart armor.

The Goal: Create lightweight, flexible protective gear (like vests or liners) that remains comfortable during normal movement but instantly hardens upon high-impact, like a bullet or shrapnel strike. The key? A special composite material filled with nanoparticles suspended in a liquid polymer.

The Rheology Puzzle: The magic lies in a phenomenon called shear thickening. Normally, stirring a fluid faster makes it flow easier (like stirring water). But some mixtures, like cornstarch and water, do the opposite: hit them hard and fast, and they resist like a solid. This is the effect scientists sought to harness and control.

The Experiment: Step-by-Step

Material Cocktail

Researchers meticulously prepared a suspension of extremely hard, tiny silica nanoparticles dispersed within a liquid polyethylene glycol (PEG) matrix. The size, shape, and concentration of particles were critical variables.

Rheological Interrogation

Using a sophisticated instrument called a rheometer, they subjected the composite material to controlled forces.

Simulating Impact

The rheometer rapidly increased the shear rate (essentially, how fast adjacent layers of the material are forced to slide past each other), mimicking the sudden, intense deformation of an impact event.

Measuring the Response

Sensors continuously measured the viscosity (resistance to flow) and stress (force per area) required to achieve each shear rate.

High-Speed Imaging

Simultaneously, high-speed cameras captured the microscopic structural changes within the material as it thickened.

Ballistic Testing

Promising formulations were then integrated into fabric layers and subjected to controlled ballistic impact tests using standardized projectiles.

Results and Analysis: Liquid to Solid in a Blink

The data revealed a dramatic transformation:

- At Low Shear Rates: The composite behaved like a viscous liquid, flowing easily. Viscosity remained relatively constant and low.

- At a Critical Shear Rate: A sharp, non-linear increase in viscosity occurred – the shear-thickening effect kicked in. The material effectively transitioned from liquid-like to solid-like behavior within milliseconds.

- Under High Shear/Impact: Viscosity spiked massively, dissipating the impact energy. The ballistic tests confirmed significantly improved resistance to penetration compared to the base polymer or fabrics alone.

| Shear Rate (1/s) | Viscosity (Pa·s) | Observed Behavior | Real-World Analogy |

|---|---|---|---|

| 0.1 - 10 | 50 | Flows slowly, viscous | Honey at room temp |

| 50 | 60 | Starting to thicken | |

| 100 (Critical) | 500 | Rapid thickening | Sudden stiffening |

| 500 | 10,000 | Solid-like resistance | Stiff paste |

| 1000 | 50,000+ | Very high resistance | Near-solid block |

| Sample | Projectile Velocity (m/s) | Depth of Penetration (mm) | Energy Absorbed (J) | Outcome |

|---|---|---|---|---|

| Base Polymer (PEG) | 300 | Full Penetration | Low | Failed |

| Standard Fabric | 300 | Significant Penetration | Moderate | Partial Failure |

| STF Composite Fabric | 300 | Minimal Penetration | High | Success (Stopped) |

| STF Composite Fabric | 350 | Reduced Penetration | Very High | Success (Stopped) |

Why This Matters

This experiment demonstrates the power of harnessing fundamental rheological principles (shear thickening) for practical applications. By precisely controlling the particle interactions through modeling and formulation, scientists can design materials that are adaptable – soft when you need flexibility, hard when you need protection. This has profound implications for safety equipment, vibration damping, and even adaptive robotics.

The Scientist's Toolkit: Cracking the Flow Code

Developing and testing these smart materials requires a specialized arsenal. Here are some key reagents and tools featured in rheology research like the shear-thickening armor:

| Reagent/Material | Primary Function | Why It's Important |

|---|---|---|

| Silica Nanoparticles | Dispersed phase causing shear thickening | Hard particles that jam under high force, increasing viscosity dramatically. |

| Polyethylene Glycol (PEG) | Liquid polymer matrix (continuous phase) | Biocompatible, tunable viscosity base that suspends particles effectively. |

| Surface Modifiers | Chemicals coating nanoparticle surfaces | Control how particles interact with each other and the polymer, crucial for triggering thickening at the right stress. |

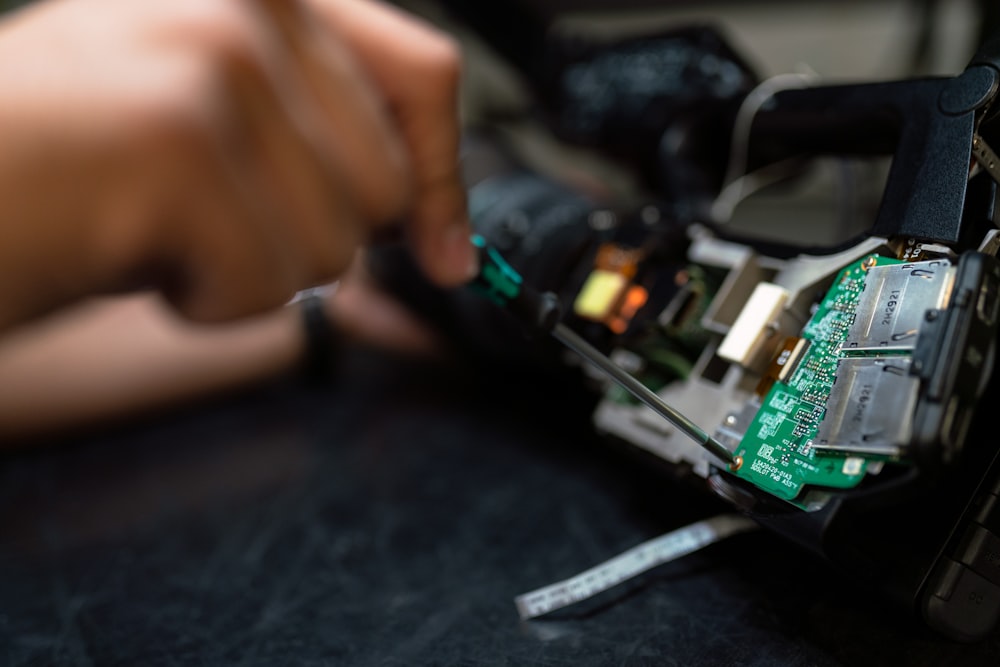

| Rheometer | Instrument applying controlled stress/strain & measuring response | The core tool for quantifying flow properties (viscosity, elasticity) under precise conditions. |

| High-Speed Camera | Capturing ultra-fast deformation events | Visualizes microscopic structural changes (particle jamming) happening during thickening/impact. |

| Computational Fluid Dynamics (CFD) Software | Simulating complex fluid flow & deformation | Models material behavior under virtual conditions, guiding experiments and predicting performance. |

Rheometer

The essential instrument for measuring flow properties under controlled conditions.

Nanoparticles

Tiny particles that enable smart responses in advanced materials.

The Future is Flowing

The 3rd International Conference on Rheology and Modeling of Materials illuminated a path where understanding the intricate dance of molecules and particles under force unlocks incredible possibilities. By merging sophisticated experiments like the shear-thickening armor study with powerful computer models, scientists are no longer just observing material behavior – they are learning to predict it, design it, and harness it.

Advanced Protection

Lighter, more effective armor for military and civilian applications

Medical Breakthroughs

Injectable therapies that adapt to physiological conditions

Smart Manufacturing

Materials that optimize their own processing conditions

From life-saving armor and innovative medical treatments to more efficient factories and sustainable materials, the insights flowing from conferences like IC-RMM3 are shaping a future built on mastering the secret life of goo. The next time you struggle with ketchup or marvel at a flexible screen, remember: there's a whole world of complex flow being decoded, one experiment and one model at a time.